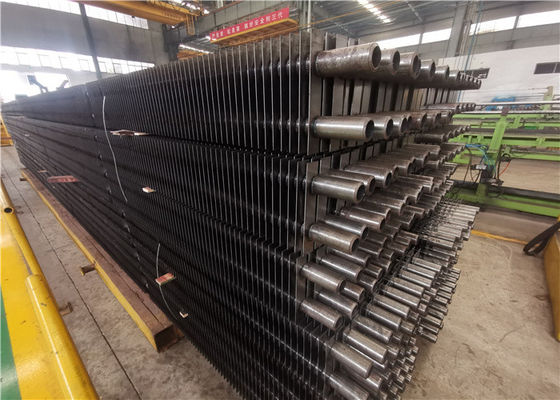

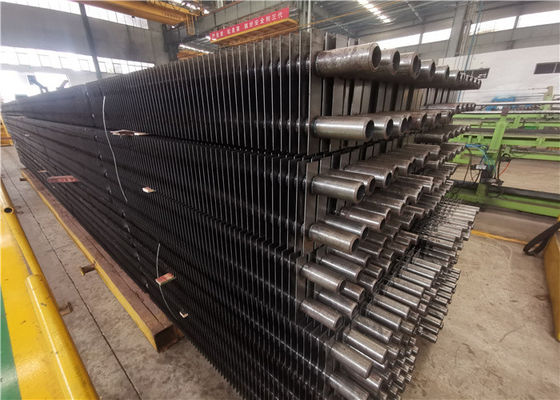

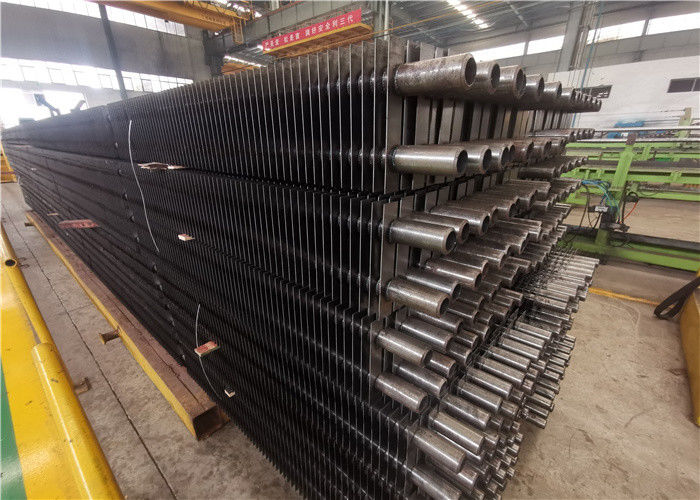

Compact Structure Heat Exchanger H Finned Tube Economizer for CFB Boiler

Product Introduction of boiler fin tube

Advantages of H-finned tube:

The H-finned tube is the main heat exchange component in the whole exhaust gas boiler, and the H finned tube has the following advantages.

(1) Excellent wear resistance

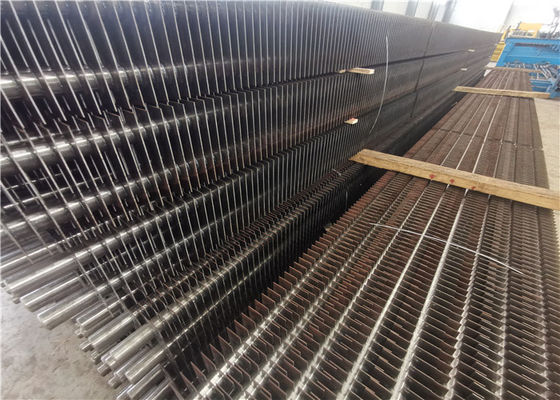

The H finned tube heat exchanger is arranged in line, and the H fins separate the space into several small areas, which have the effect of equalizing the air flow, comparing to the smooth tube heat exchanger with the staggered arrangement and the spiral finned heat exchanger And so on, in the same other conditions, the wear life is higher 3~4 times.

(2) Fouling reduced

The formation of fouling occurred in the dorsal side and windward side of the tube. The staggered arrangement of the tube is easy to flush the tube bundle, the fouling at back side is less. It has a good self-cleaning function at the appropriate wind speed. On both sides of the H finned tube are formed straight channel, soot, it can get the best soot effect while adopting soot blower.

(3) Reduce the resistance of exhaust gas

As the H fins form straight channels on both sides, and the spiral angel of the spiral fins steer the direction of the airflow, the fins are prone to fouling and have a greater flue resistance than the H fins. Therefore, the use of H-finned tube can reduce the wind resistance, reduce the fan operation and investment costs.

Boiler H finned tube economizer is a kind of boiler parts, to have two steel circular symmetry to be welded on fluorescent tubes to form ins positive shape much like letter "H", so-called H-fin tube. H finned tube economizer widely used in utility boilers, industrial boilers, marine power, such as the tail of heat exchanger components.

Our products can be modified according to our customers' needs and the situation.we design and manufacture safe,reliable and efficient H-fin tubes.it has also completed stand-alone product quality assurance systems.Production of H-fin tubes are with high heat transfer efficiency, they have flue gas resistance and are designed for a small space.

| Technical parameters |

The high degree of fin 0-16mm(or outside diameter of fin φ25-φ75);

Pitch of fins 2.0-5.0mm; Length of finning tube 0.5~ 14m. |

| Single metal rolling finning tube |

Pure aluminum 1060 or aluminum alloy 6063,6061.

Outside diameter Shall be less than 40mm |

| Double metal rolling finning tube |

Tube-based protection from the outer layer of aluminum

tubes, corrosion-resistant, Tube-based can be made of carbon steel pipe,in addition to,stainless steel tube and copper tube can also be used, as well as titanium alloy tube |

| Package |

The aluminum finned tubes are well packed in plastic film in the inner and steel fram

in the outer |

Make the craft:

steel tube polishing-tooth punching on steel strip-Solid rolling on steel trip-High frequency welding-Hydrostatic pressure test, chamfering, polishing-Quality inspection -Packaging

Produce method:extruded & serrated

Application:

air cooler, fired heater, heat exchanger, marine boiler, economizer, power plant boiler, HRSG boiler, waste heat recovery unit, air heater etc

Characteristic:1.Anti-corrosion2.Anti-wear3.Lower contact resistance 4.Higher Stability

Specifications of boiler fin tube

1). Add the heat exchange area and reduce the number of tubes, also increase the fume flow section area to reduce the fume speed and abrasion.

2). H type fin tube can be made to double H type fin tube, high rigidness to fit long tube row.

3). H type fin economizer arranged in line to make the space into many small zones, averaged air flow to reduce the abrasion.

4). With straight channel to gain the best ash-blowing effect.

5). The compact structure to reduce the weight and reduce the manufacturing cost.

| Base Tube Material |

Stainless Steel, Carbon Steel, Alloy Steel, Copper Alloy,Aluminum ,SA179 |

| Fin Material |

Aluminum, Copper Alloy, Stainless Steel, Carbon Steel |

| Standard |

ASME SA213/ASTM; ASME EA 106, ASME SA178, ASTM B1111 |

| Fin depth |

0.5-3mm |

| Base pipe O.D |

12.7-18mm |

| Fins per inch |

8-20Nos (as customer's request) |

| Test Requirement |

Physical Property Test, Chemical Composition Analysis, Non-Destructive Test, Other Inspection and Test as customer's requirement. |

| Application |

Air Cooler, Charge Air Chiller, Condenser, Evaporator, Fluid Cooler, Gas Cooler, Oil Cooler, Radiator, Refrigeration, Steam to Air Heat Exchange, super heater etc. |

Company Profile

Zhangjiagang Hua Dong Energy Technology Co., Ltd. is a high-tech enterprise specialized in producing all kinds of stainless, carbon and alloy steel tubes and pipes, steel plates which are widely used in the field of boiler&heat exchanger, energy, petrochemical, mining, food, paper, gas and fluid industry. And we have passed the attestations including ASME, TUV, Grade A, ISO9001, EN12952, EN10216, SO3834.

The company is the subsidiary of Zhangjiagang Hua Dong Boiler Co., Ltd, which is the most leading boiler and boiler parts manufacturer in China with a history of 35 years and annual turnover of 110 million U.S.A. dollars. Our products have been exported to over 30 countries like United States, Australia, Vietnam, Pakistan, Albania, Cambodia, India, Indonesia, South Korea, the Philippines, Turkey, Saudi Arab, Germany, Russia, Chile, Syria, Thailand, Bangladesh, France, Algeria, Mongolia and Singapore, Cuba, Iraq, Italy, Spain, Japan, Yugoslavia, Sri Lanka, the Czech republic, kyrgyzstan, Canada, Malaysia, the United Kingdom and so on.

Location:

Our company locates in Zhangjiagang city which is a port city, and is only 120km far away from Shanghai, 60km far away from Suzhou and 60km far away from Wuxi. The traffic is very convenient.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!